Email cannot be empty

Password cannot be empty

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Offset Ink Production Line

-

USD 10,000.00 ~ USD 50,000.00/set

1/ set (Min. Order)

1.how to produce offset ink

Stage 1: Pre-Dispersion (Paste Mixing)

The process begins in a high-speed disperser (HSD) or a double-arm paste mixer. Here, the powdered pigment is combined with the resin and vehicle.

-

Goal: To wet the pigment particles and break down the largest agglomerates (clumps).

-

Process: The powerful mixer creates a vortex, pulling all materials together. The result is a thick, rough paste that is far from smooth but has all the components uniformly distributed. This paste is often called a "chip" or "masterbatch."

Stage 2: Milling (The Heart of the Operation)

This is the most critical step for achieving color strength and fineness. The pre-dispersed paste still contains pigment agglomerates that are too large for high-quality printing. They must be ground down to a microscopic size.

This is done using a series of mills. The type of mill depends on the ink's viscosity and the pigment's hardness.

-

Three-Roll Mill: A classic and highly effective mill for high-viscosity pastes. The paste is fed between a series of three horizontally positioned rollers spinning at different speeds. The tremendous shear force created between the rollers grinds the pigment particles down to a fine, uniform size (typically less than 10 microns).

-

Bead Mill: More common for medium-viscosity inks. The paste is pumped through a chamber filled with tiny grinding media (e.g., zirconia beads). The intense agitation and collision between the beads provide the shear force needed to disperse the pigment.

Quality control technicians regularly take samples during milling to check the fineness of grind using a Hegman gauge, ensuring the product meets strict specifications.

Stage 3: Letdown and Formulation

Once the pigment is perfectly dispersed and milled to the correct fineness, the concentrated paste is transferred to a large mixing tank, often called a letdown tank.

Here, the remaining components are added:

-

Additional vehicles and resins to achieve the final ink consistency and tack.

-

Additives: Waxes for rub resistance, driers to accelerate oxidation, and other compounds to fine-tune the ink's properties.

This stage is where the final ink formula comes together. Large mixers gently but thoroughly blend everything into a homogeneous product.

Stage 4: Quality Control (QC) Testing

Before packaging, every batch must pass a battery of rigorous QC tests to ensure it performs identically to previous batches. Key tests include:

-

Color Match: Compared spectrophotometrically to the standard.

-

Viscosity and Tack: Measured with precise viscometers and tackometers to ensure proper flow on press.

-

Drying Time: Tested on a lab simulator.

-

Fineness of Grind: Re-checked with the Hegman gauge.

Any batch that fails is adjusted and re-tested until it's perfect.

Stage 5: Packaging and Storage

The approved ink is then pumped to packaging stations. Depending on its end use, it can be filled into:

-

Small cans for individual press units

-

Large pails (5-gallon/20-liter)

-

Even larger bulk containers for high-volume printers

The finished products are labeled, palletized, and stored in a controlled environment before shipping to printers around the world.

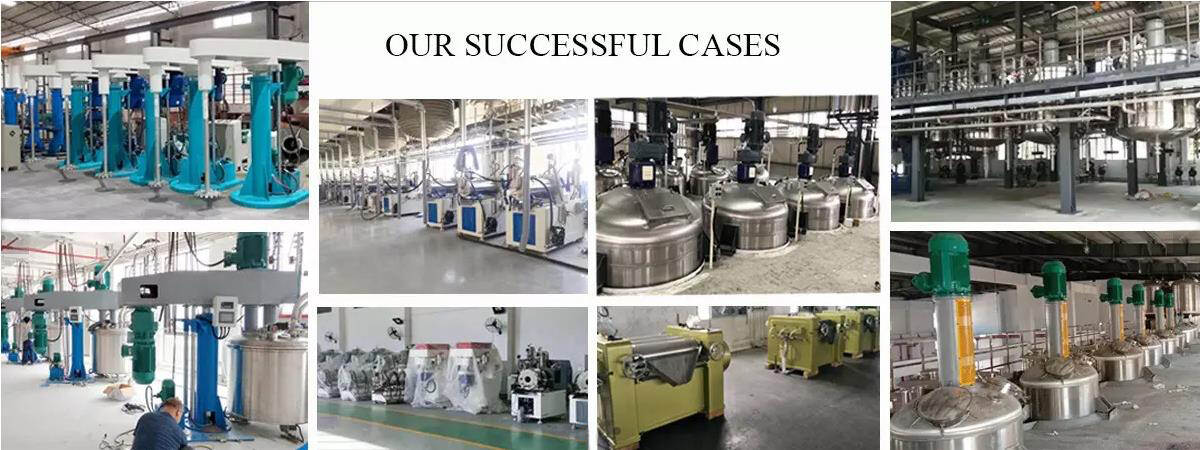

2.project showcase

3. TGM Factory Profile:

TGM Chemical Machine Co., Ltd is a group enterprise. We have brands like TGM, Pengchang and Tongpeng.

We are a leader in the field of chemical machine industry, with 18 years of industry experience.

We have professional R&D design team, strong technical support, skilled production team, reliable after sales service, flexible customized solutions,

to meet your various standards and non standard equipment procurement needs. We committed to providing the complete and professional chemical equipment solutions.

We integrate, design, development, production, sales and training together.

Our products scope: Disperser, Bead Mill, Basket Mill, Mixer, emulsifier, Mixing kettles, Reactor, Filling machine, Bag filter, Pumps, Zirconium Bead, 3 roll mill, and other accessories.

Our machines help you to make ideal products: paints, coatings, inks, pigments, dyes, thinner, hardener, emulsions, varnish, spin finish, putty, glues, adhesives, viscous pastes, concrete Admixtures,

PCVC solvent cement, liquid resins, sealants, silicone sealant, lithium battery, electronic slurry&paste, pulps, silicon dioxide, liquid rubber, pesticide, liquid fertilizer, disinfectant, liquid detergent, gel,

lotions, shampoo, body wash, liquid soap, hand sanitizer, liquid wash, nail polish, creams, and so on.

We could offer individual machine or full production lines for your plants.

4. What are advantages of your factory?

1) Our factory is a leader manufacture of Chemical machine With 18 years of Industry experience. We have a lot Technology Patents & Product Patents;

2) Our factory has Professional R&D Teams, High Technical Supports, Skilled Production Team, Reliable After Sales Service, Flexible Customized Solutions;

3) Our factory is the leader of this industry, named with high and new technology enterprise;

4) Our factory has plenty of industry experience, we could offer you the complete palnt planning.

5. Who are your factory's clients? Could you list some of them?

AKZONOBEL, JUNTON, PPG, NIPPON, DABAO, BURGER, MAYDOS, RAINBOW, HITECH COATING, CHINA PAINT, CHANGJIANG COATING, TOA, LYNWON PIGMENT,

PEONY INKS, TL INKS, ZR INKS, SAKATA INKS, KINGSWOO INKS, DIC INKS, ANLI, ACHILLES, REPOW GROUP, SHINETSU ADHESIVES, JUSHI, XINGLONG PESTICIDES...

6. What certificate your factory could offer?:

CE, BSC, CNEX, ISO, patents.

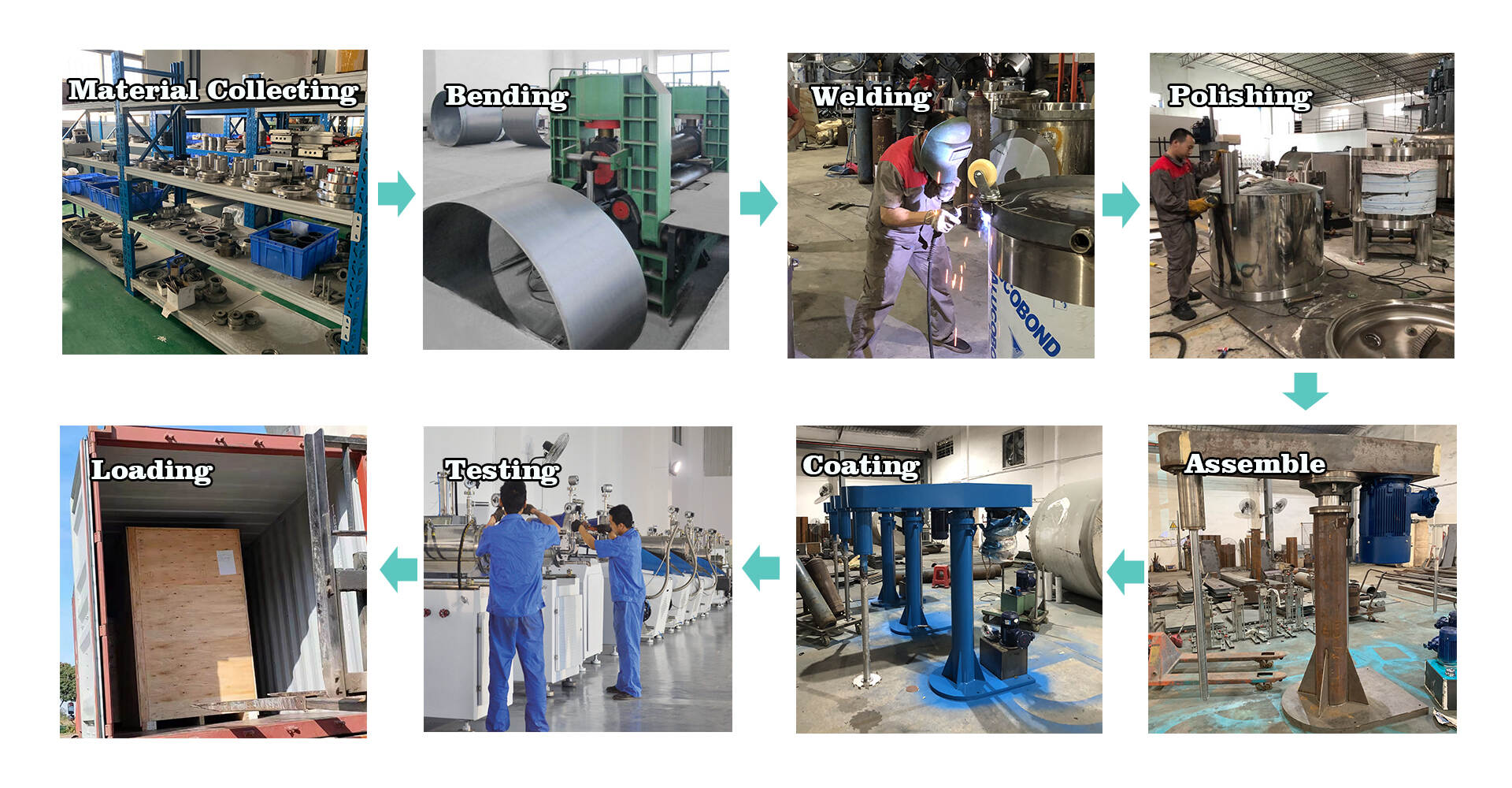

7. Manufacture Processing:

Our Chemical Machines are strictly quality control at every single production step, after quality past, we will move to do next step production.

Our Chemical Machines production process: raw materials preparing-cutting/bending materials-welding-polishing-assembling-coating-testing-packing-loading.

8. Packing And Shipping: